Glossary of Terms

On this page you will find definitions and explanations of commonly used terms and phrases we use to explain our engines and packages.TABLE OF CONTENTS

- "SHORT BLOCK"

- "LONG BLOCK"

- "TURN-KEY"

- "DROP-IN-READY"

- "ULTIMATE TURN-KEY PACKAGE"

- "DYNO TESTING"

- "HEADS"

- "CNC PORTED"

- "BLOCK"

- "ENGINE BLOCK DECKING" / "DECKING"

- "RE-SLEEVE"

- "CAM / CAMSHAFT"

- "CAM LOBE / LOBE"

- "DEGREEING A CAM"

- "INCONEL VALVES"

- "CRANK / CRANKSHAFT"

- "ULTRA BILLET CRANKSHAFT"

- "RODS / CONNECTING RODS"

- "ROTATING ASSEMBLY / INTERNALS"

- "CARB / CARBURETOR"

- "SINGLE-PLANE -vs- DUAL-PLANE MANIFOLD"

- "MPEFI"

- "REMOTE TUNING"

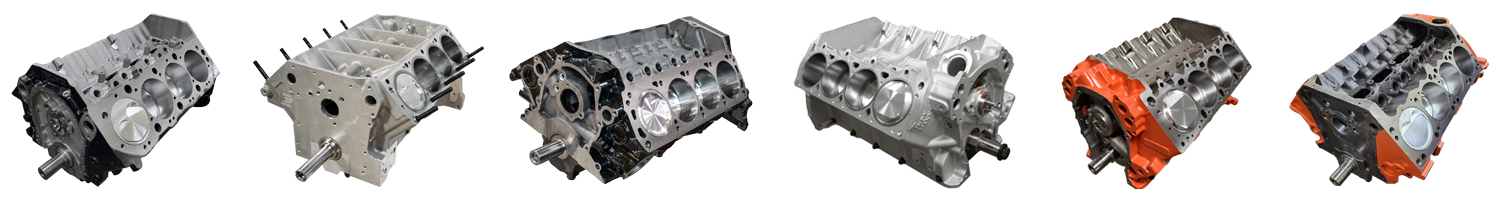

SHORT BLOCK

A short block, by definition, is an engine that has been partially assembled. It starts with the engine block, crankshaft, pistons, connecting rods and freeze plugs. Engine blocks can be made from Iron or Aluminum, depending on use and budget.

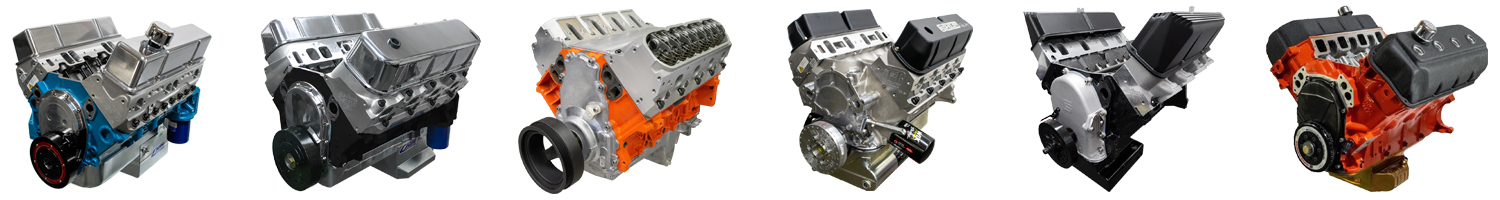

LONG BLOCK

A long block, is the short block as previously explained, plus the camshaft, lifters cylinder heads, valvetrain, timing chain, push rods, rocker arms, harmonic balancer, oil pan, oil filter, and valve covers installed. Dyno testing available.

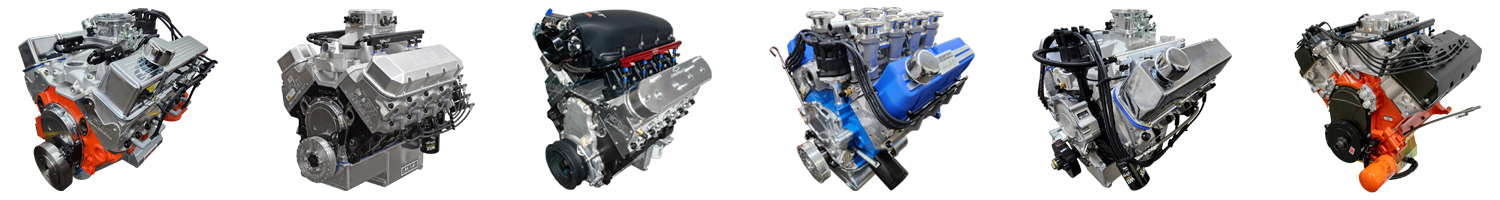

TURN-KEY

The Turn-Key engine is the short block combined with the long block, plus the addition of the intake manifold, fuel delivery system, ie; carburetors or fuel injection and ignition system, spark plugs and wires. Dyno testing is included with our Turn-Key engines.

DROP-IN-READY

Our Drop-in-Ready engine is the short block combined with the long block, plus the addition of the intake manifold, fuel delivery system, ie; carburetors or fuel injection and ignition system, spark plugs and wires, plus a complete front drive pulley system and water pump. Dyno testing is included with our Drop-in-Ready engines.

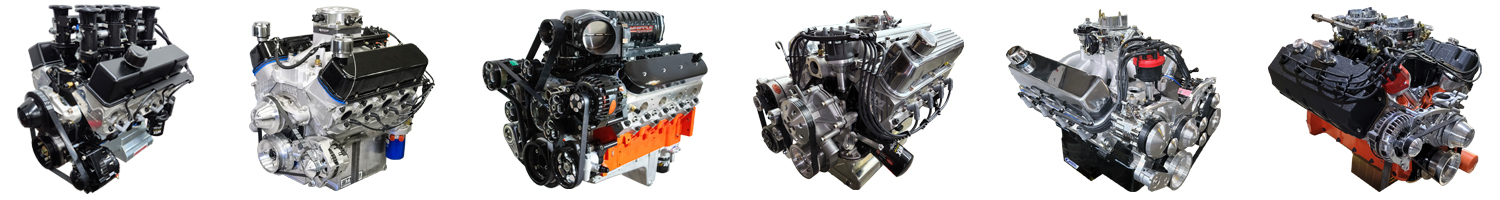

"ULTIMATE TURN-KEY PACKAGE"

Our Ultimate Turn-Key Package is the most comprehensive package on the market for getting your project running and running right! We not only build custom engines, but we have an in-house car shop where our technicians fabricate, assemble, and modify complete car builds from the ground up. If it can be done, we can do it and that experience is what has helped us to develop our Ultimate Turn-Key Packages. These packages include a complete dyno tuned, custom built engine with ignition and front drive pulley kit, ignition system and/or engine management system, fuel delivery system with vehicle specific fuel tank, fuel lines and fuel pump, cooling system with custom Aluminum radiator, Automatic or Manual transmission built to handle you power level, flywheel, or flex-plate, clutch or torque converter. Everything is assembled specific to your build and ships all together in one large crate, right to your door. (Car not included)

"DYNO TESTING"

Dyno testing evaluates the torque and rotational speed of an engine and simulates the drag generated by your vehicle. This is a crucial step in automotive testing to ensure the engine is performing at its peak potential before shipping out to you. A dyno measures Horsepower, Torque and allows us to "fine tune" your engine before it leaves our facility, to ensure your build is a hassle free experience.

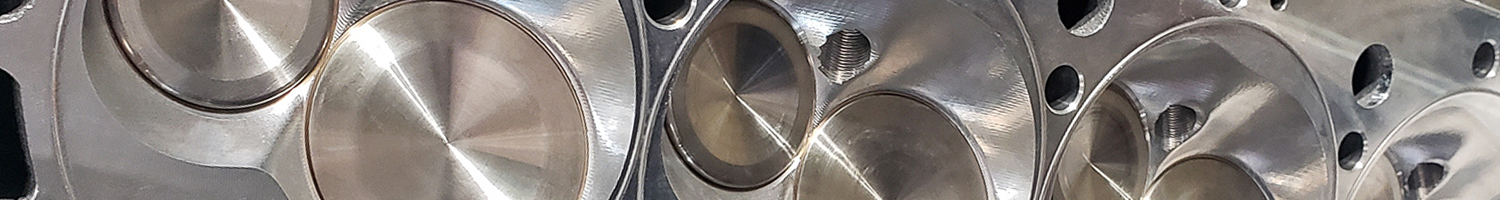

"HEADS"

The cylinder head (often abbreviated to simply "head" or "heads") sits above the cylinders and forms the roof of the combustion chamber. The cylinder head contains inlet and exhaust passages, coolant passages, intake and exhaust valves. American V8 engines have a single cylinder head on each side of the engine, one per bank of cylinders. We offer "as-cast" heads as well as CNC ported heads for more horsepower.

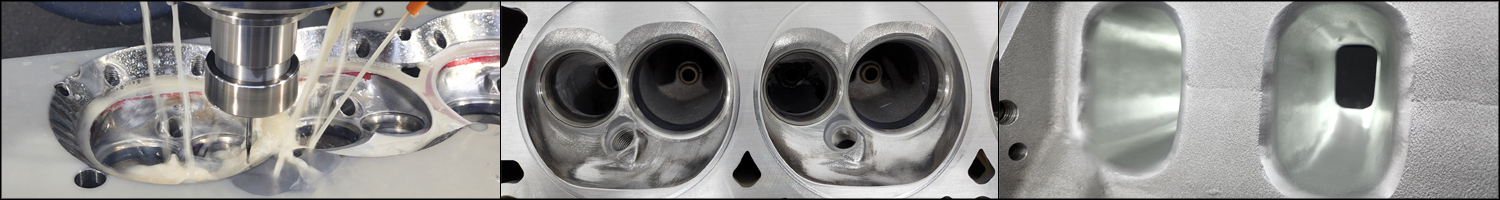

"CNC PORTED"

Cylinder head porting also computer numerical control, and commonly called CNC, refers to the process of modifying the intake and exhaust ports of an internal combustion engine to improve their air flow. Cylinder heads, as manufactured, are usually suboptimal for racing applications due to being designed for maximum durability. Ports can be modified for maximum power, minimum fuel consumption, or a combination of the two, and the power delivery characteristics can be changed to suit a particular application. CNC porting helps to generate more horsepower and torque in your engine. All CNC porting is done in-house at Prestige Motorsports which allows us to maintain a higher level of quality control within your engine build.

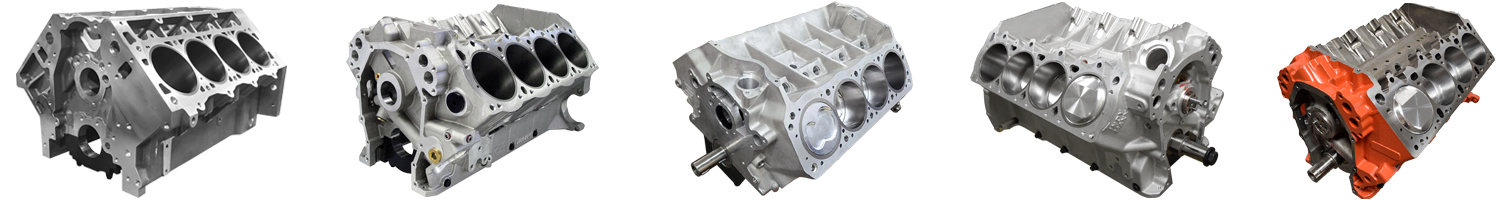

"BLOCK"

A cylinder block (engine block or the block) is the structure which houses the cylinders, plus any cylinder sleeves and coolant passages, camshaft, lifters, timing chain, oil pump, crankshaft, rods, and pistons. The heads sit on top of the engine block. This is where most of the stress and power in an internal combustion engine is produced. Our blocks go through a rigorous testing and machining process to ensure a quality product every time.

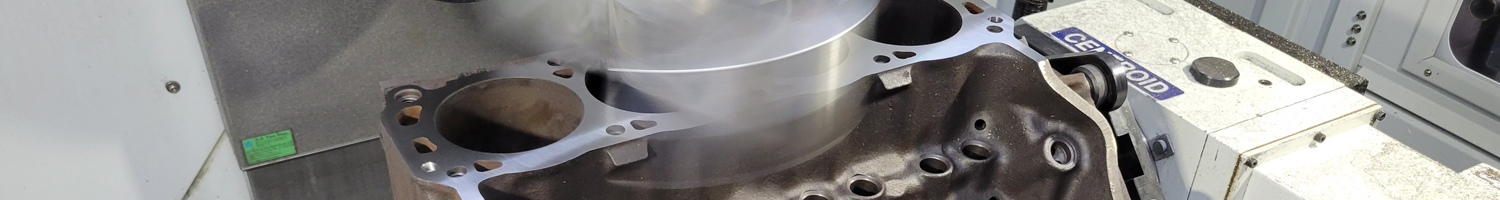

"ENGINE BLOCK DECKING / DECKING"

Decking an engine block is the process of cutting down the portion of the block where the cylinder heads meet. It is sometimes necessary to remove material from this part of the block to square up the cylinder heads. The deck of the block should be perpendicular to the crankshaft center line. A block is also decked to ensure a good, flat surface to achieve a good gasket seal. Engine blocks are also decked to create proper deck height, this is the distance between the crank center-line to the deck surface. Deck height is precisely calculated to dial-in compression and proper quench area plus accommodates gasket thickness. All of this is done in the interest of creating a good mixture of the air/fuel charge and ultimately more efficient combustion. Whenever you change deck height, you must also make sure that there is sufficient piston-to-valve clearance.

"RE-SLEEVE"

Cylinder re-sleeving is the process of replacing or adding a cast iron sleeve to the engine blocks cylinder hole with a replacement cast iron or harder metal sleeve. The primary reason for sleeving an engine is to either repair a cylinder bore or protect it from damage in the first place. Sleeves can also be used to restore a particular bore size if a cylinder has to be “bored out” to repair a cracked or otherwise damaged engine. Prestige Motorsports will use a sleeve to “overbore” the cylinder to increase the engine displacement and add extra stength to the engine block overall.

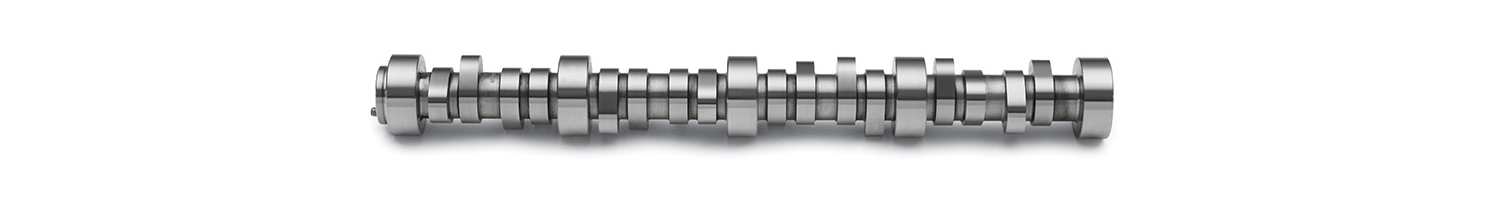

"CAM / CAMSHAFT"

A camshaft(cam) is a shaft that contains a row of oblong lobes, to operate the intake and exhaust valves and mechanically control ignition systems and early electric motor speed controllers. The camshafts in piston engines are usually made from steel or cast iron, and the shape of the cams greatly affects the engine's characteristics. (Idle quality, rpm range, horsepower range and torque range)

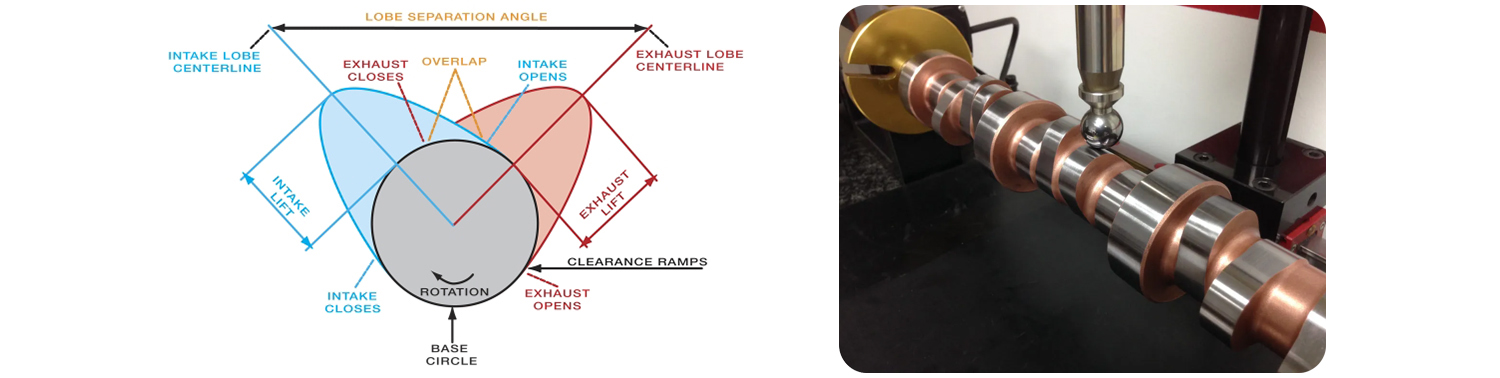

"CAM LOBE / LOBE"

The camshaft has "lobes", these oblong shapes are specific to each application and determain how far the valve opens and for how long. It also determains valve overlap. Camshafts lobe shape and size is what affects the engine's characteristics. (Idle quality, rpm range, horsepower range and torque range). We use custom ground camshafts proprietary to our applications and custom built engines.

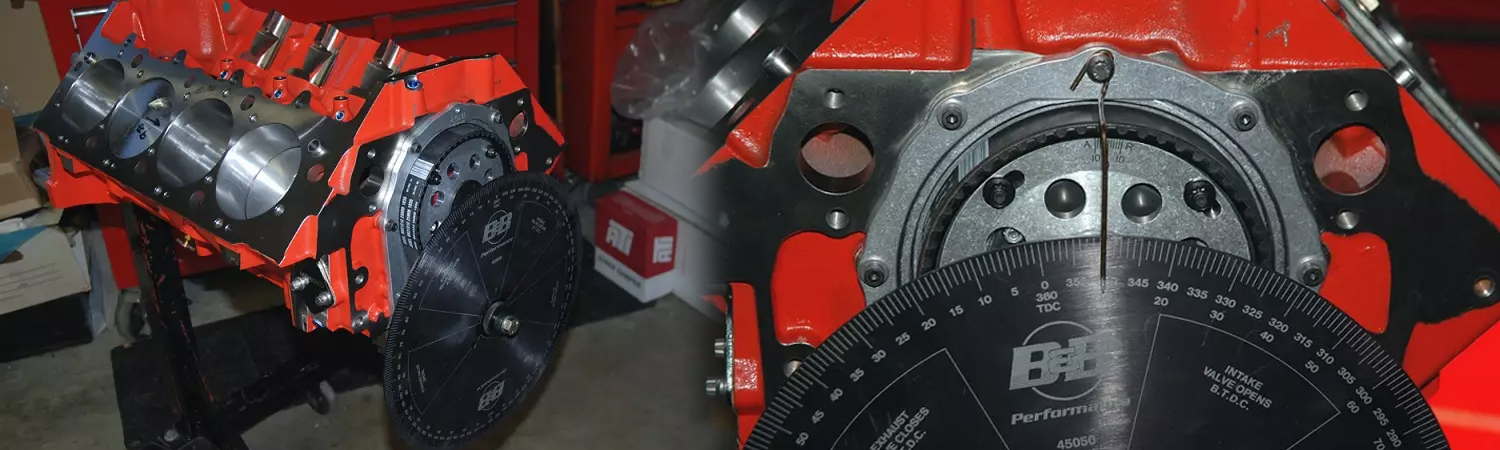

"DEGREEING A CAM"

When a camshaft is “degreed” it means the camshaft position in the engine has been synchronized with the crankshaft position. Degreeing the cam is the only positive means to determine if the rise and fall of the pistons correctly matches the opening and closing of the valves. Several degrees of misalignment can have a profound effect on engine operation (which we’re pretty sure is no secret to most of you). In a perfect world, you’d need only line up the timing marks on the timing gears (timing chain sprockets or pulleys) and be good to go. But there’s a good chance dimensional stack ups will catch up to you. Things like tolerances in the camshaft, crankshaft, timing chain and sprockets add up. Which is why checking the relation of the camshaft to the crank (or “degreeing the cam”) is the only option.

"INCONEL VALVES"

Inconel valves are made from a Nimonic 751 alloy which has better resistance to heat than stainless steel valves. The Inconel valves are only used on the exhaust side, it is the only side that is needed to use a higher temperature alloy. We commonly use inconel valves on our extreme duty application, Supercharged, Turbocharged, Nitrous Injected, Airboat and Marine engines.

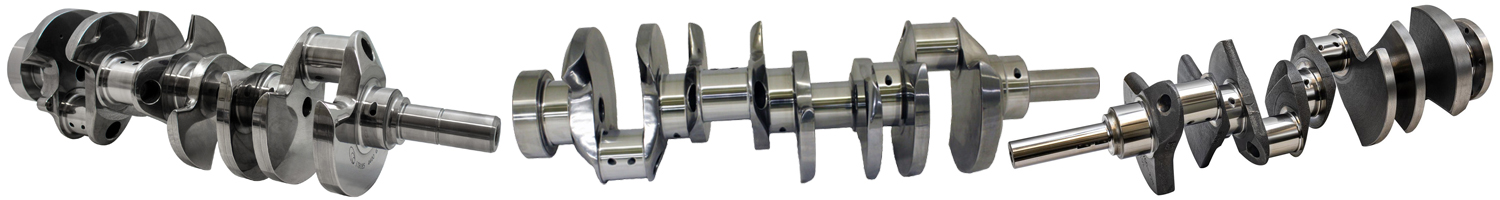

"CRANK / CRANKSHAFT"

A crankshaft is a mechanical component used in a piston engine to convert the reciprocating motion into rotational motion. The crankshaft is a rotating shaft containing one or more crankpins, which are driven by the pistons via the connecting rods. We use cast-iron or forged-iron crankshafts depending on the power level and use of your engine. Forged-iron crankshafts are for high horsepower and severe-duty applications. We also offer pendulum undercutting which is a machining process to exact tolerances and reduces crankshaft weight to help your engine rev quicker, used in high horsepower and high rpm applications.

"ULTRA BILLET CRANKSHAFT"

Ultra billet crankshaft's are machined from Premium Grade (Para-Pure) Timken alloy steel. This high quality specialty steel has been formulated to create a level of toughness that is unmatched in the crankshaft industry. We have a wide range of part numbers for a variety of popular engines. Any main journal, rod journal, post configuration, stroke or other specialized characteristic that you may require can be provided. Each Ultra billet crankshaft is uniquely machined with our Ultra-Shed counterweight profiles. The Ultra-Shed leading edge profile gently moves oil away from the oncoming counterweight while the directional trailing edge directs oil away from the oncoming rod journal. The Aero-Shed super finish will give you a crankshaft that is totally stress-riser free and incredibly aero efficient. When the Ultra-Shed and Aero-Shed processes are combined, the result is a crankshaft with the lowest coefficient of drag in the industry.

"RODS / CONNECTING RODS"

A connecting rod is an engine component that transfers motion from the piston to the crankshaft and functions as a lever arm. Connecting rods are commonly made from steel or aluminum alloy and are designed to withstand dynamic stresses from combustion and piston movement. The small end of the connecting rod connects to the piston with a wrist pin. The wrist pin, or piston pin, provides a pivot point between the piston and connecting rod. Spring clips, or piston pin locks, are used to hold the piston pin in place. The big end of the connecting rod connects to the crankpin journal to provide a pivot point on the crankshaft. A rod cap is the removable section of a two-piece connecting rod that provides a bearing surface for the crankpin journal. The rod cap is attached to the connecting rod with two hardened rod cap bolts for installation and removal from the crankshaft. As you can see in the images below the type of material and design of the rods will determine its power level usage.

"ROTATING ASSEMBLY / INTERNALS"

Internal combustion engines use a variety of parts to create the rotating assembly. The crankshaft is the main piece which endures a huge amount of stress during operation. The connecting rod and pistons move in opposite directions and require a good cylinder wall seal to prevent loss of compression and burning oil. The assembly must be balanced for smooth and safe operation at high RPM, horsepower and torque levels.

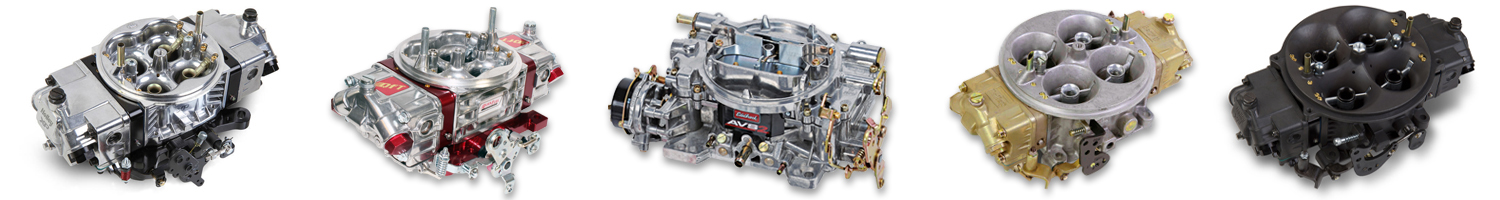

"CARB / CARBURETOR"

A carburetor helps to mix fuel and air together for facilitating efficient and complete combustion inside an internal combustion engine. This device passes the mixture of fuel and air to the intake manifold (a device delivering air/fuel mixture to the cylinders) of an internal combustion engine. We use the Holley 4150-style carb for mild to moderate 347-cubic inch engines all the way up to 582ci engines and we use the larger 4500-style carb for higher horsepower 582ci and larger engines. Our engines come with 1 or 2 carburetors depending on your specific build.

"SINGLE-PLANE -vs- DUAL-PLANE MANIFOLD"

Note how the single plane offers a more direct path to the intake ports but this also shortens the runner length which hurts low-speed torque. The dual plane uses longer runner lengths which drastically improve low- and mid-range torque, making it a better choice for a street driven engine.

"MPEFI"

In Multi-Point Electronic Fuel Injection (MPFI) technology, every cylinder in the combustion chamber of the engine is given an injector at the front of their inlet valves (outside the intake port), which is why it is also called “Port Injection”. MPEFI engine management systems control the fuel injector for the most accurate air/fuel mixture and can also control your electronic controlled transmission shift points. These engine management systems also offer a fuel gauge and engine monitoring display which can replace old or unusable gauge clusters. We use and highly recommend upgrading to MPEFI on your next build for easier and more accurate tuning. MPEFI also offers the option of remote tuning via laptop.

"REMOTE TUNING"

Holley MPEFI engine management systems offer the option of “remote tuning” via laptop and an internet connection. Our complete engine packages come with the exact Holley Engine Management System that the motor was tuned with on our dyno, so when you get it, it is a simple plug-and-play installation. By including the engine management system that your engine was dyno tuned with, and its self-learning capability, you will be up and running in no time! Prestige Motorsports' remote tuning service will allow you to connect one-on-one with our tuners to communicate any issue and get real-time solutions, allowing you more time to enjoy your project, rather than working on it.